If you considered buying solar panels for your home or off-grid cabin, you’ve probably come across terms such as monocrystalline and polycrystalline solar panels.

And these are no sales gimmicks like “surgical steel” or “non-slip handle”.

These two words refer to different technologies for manufacturing solar panel cells.

But why is that important?

Is there any significant difference?

As an electrical engineer, I’m well aware of both cell types and their industrial and commercial use.

But as home solar systems are becoming increasingly available, I have more and more people asking me, “What should I get? Monocrystalline vs. polycrystalline.”

I wrote this guide to help homeowners choose the best option for their solar system.

What are Monocrystalline Solar Panels?

Monocrystalline solar panels are solar panels made from monocrystalline solar cells or, as the industry calls them, wafers.

Monocrystalline solar panels consist of cells that are cut from a single silicon crystal. This feature gives them a uniform black look which users come to prefer. Since they are made from a single silicon crystal, these cells have fewer impurities. This allows them to perform better in high heat and lower-light environments.

These solar panels are generally considered a premium solar option due to their black color, higher efficiencies, and sleek aesthetics.

How It’s Made

In the lab, silicon crystal is grown into a cylindrical log shape called an ingot which is sliced into thin discs. Each disc is cut along the edges to form an octagon — a final shape of a solar cell.

This is important because when the solar cells are placed in the solar panel, the octagon shape helps fit a maximum number of solar cells for a given surface.

As a result, the manufacturing process for monocrystalline cells is more wasteful than the alternatives. Those corners that are cut from silicon wafers to make cell-shape discs have no further use.

This also makes these panels more expensive to produce and that price difference is passed on to a buyer.

What are Polycrystalline Solar Panels?

Polycrystalline solar panels are also

made from silicon crystals. But in this case, instead of using a single crystal ingot,

many fragments of silicon are melted together to form wafers for the panel.

This manufacturing process gives polycrystalline panels a deep blue color.

If you look at them up close, you’ll see that the texture and color are uneven due to the way bits of silicon are blended together.

As there are more crystals in each cell, there’s less free space for electrons to move, which makes them less efficient than monocrystalline panels.

How It’s Made

To make polycrystalline solar panels, silicon crystal is left to cool down and fragment on its own. These fragments are melted at high temperatures and shaped into cubes that are cut into thin wafers.

So in this process, we don’t end up with a single silicon crystal but many different crystals molded, shaped, and cut into wafers.

You can compare it with baked potato chips: sliced from whole potatoes vs. made from potato mash pressed and molded into uniform chips.

The polycrystalline process allows for more cells to be produced from the same amount of raw materials.

This technology also produces less waste because there’s nothing to shave off or discard. All the raw materials are used in manufacturing.

As it is less demanding to produce polycrystalline than monocrystalline cells, the end product is also cheaper for the end-user.

Monocrystalline vs. Polycrystalline Solar Panels?

Let’s now compare these two types of solar panels in categories that matter the most to end-users.

Cost

Monocrystalline solar panels use solar cells of high purity and require an altogether more complex manufacturing process. This makes them more expensive than polycrystalline panels.

However, homeowners often forget that a solar system includes other costs, as well, which are pretty much the same for both panel types. First of all, there's the solar inverter, electrical protections, wiring, rooftop mounts, labor, as well as permits and inspections.

Polycrystalline solar panels cost less but they are also less efficient. This means you can see a better return on investment with monocrystalline panels, especially if you’re limited by the number of panels.

Also, both types of panels are eligible for the federal solar tax credit.

Winner: Polycrystalline Solar Panels

Efficiency

Monocrystalline solar panels are generally more efficient than polycrystalline solar panels. This comes from the fact that their cells are cut from a single silicon crystal. To put it simply, the single crystal contains no impurities and the electrical current has less resistance to move through the cells.

But what is efficiency in solar panel terms?

Imagine you had 2 solar panels, one with an efficiency of 10% and the other with 20%.

If you expose both panels to the same amount of sunlight for the same duration, the second one will generate almost double the electricity.

The top-performing monocrystalline solar panels on the market reach efficiencies of 23%. The standard bestseller models typically have an efficiency of 15-20%.

In the same range, polycrystalline solar panels have efficiencies between 12% and 16%.

However, at the end of the day, the difference between these two solar panel types is not that big, especially if we’re talking about mid-range products.

Winner: Monocrystalline Solar Panels

Aesthetics

Monocrystalline solar panels consist of octagonal solar cells that look like rounded squares from a distance. Since they are made of pure silicon, they have a uniform dark look because of how lights interact with pure silicon.

This type of solar panel blends more naturally with dark shingles and foliage. It also makes your solar panels less of an eyesore. This is especially important if the local homeowner’s associations have strict rules on the homes’ curb appeal.

Polycrystalline solar panels, on the other hand, have a speckled blue look, as that's how sunlight interacts with melted silicon.

When it comes to aesthetics, it’s really up to personal preferences. Some users may prefer elegant and uniform black to keep up with the roof theme, others will discover that blue panels complement the swimming pool or the sky above.

Lifespan

The lifespan of the solar panels is determined by the degradation rate or the yearly energy production loss.

Most solar panels on the market have degradation rates of 0.3% to 1%.

This means that every year, the power output of your solar system will drop by 0.3% to 1%.

Most commercially available solar panels have a yearly production loss of 0.3% to 0.8%.

Let’s say it is 0.5%.

After 10 years of use, your system will run at 95% efficiency. After 20 years, the system will still deliver 90% of its original output, and so on.

Unless there's physical damage, monocrystalline solar panels can keep running for more than 40 years, although with reduced efficiency. However, most manufacturers provide 25-30 year warranties.

In terms of lifespan, both monocrystalline and polycrystalline can well operate beyond their warrantied lifespans. That being said, polycrystalline panels have a slightly higher degradation rate.

Temperature Coefficient

The temperature coefficient is a measure of how solar cells operate in hot weather. As you may remember from science classes, heat increases electric resistance and generates losses.

In this category, monocrystalline solar panels take an edge because their temperature coefficient is very low — between -0.3%/°C to -0.5%/°C.

This means when the temperature rises 1 degree Celsius or 32 degrees Fahrenheit, a monocrystalline solar cell efficiency drops by 0.3% to 0.5%.

Polycrystalline solar panels have a higher temperature coefficient than their monocrystalline counterparts, which means they’ll have weaker output when the temperature rises.

This is something to consider if you live in a hot region.

Winner: Monocrystalline Solar Panels

Monocrystalline vs. Polycrystalline Solar Panels: Summary Table

Now to sum up the most important differences between monocrystalline vs. polycrystalline solar panels:

| | | |

|---|

| | Single pure silicon crystal | Multiple silicon fragments molten together |

| | Uniform dark squares with rounded edges | Different blue squares with sharp edges |

| | | |

| Temperature Coefficient (Losses) | | |

| | | |

| | | |

N-Type and P-Type Solar Cells: What Should You Know?

In the previous sections, we covered the two most popular technologies to process raw material into silicon wafers — monocrystalline and polycrystalline.

Now we’ll explain how those wafers are further processed to turn them into functioning photovoltaic (PV)

cells that can generate electrical current when exposed to light.

There are two types of solar cells that are created in these processes — N-type and P-type cells.

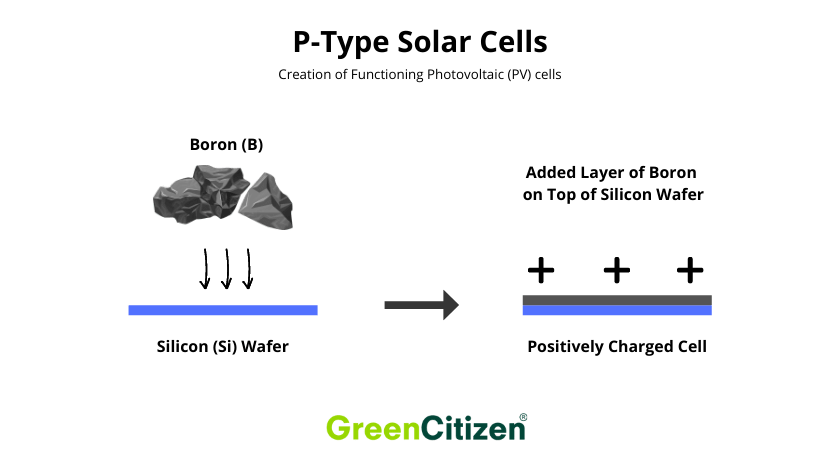

P-Type Solar Cells

P-type cells are typically built by adding a layer of boron on top of a silicon wafer. Since boron has one less electron than silicon, this combination produces a positively charged cell (P=positive).

P-type cells are prone to light-induced degradation (LID), which causes an initial drop in output as a result of light exposure. Over decades, this was the most common way to build solar cells. .

N-Type Solar Cells

N-type cells are doped with phosphorus, which has one extra electron than silicon, which creates negatively charged cells (N=negative).

N-type cells are immune to boron-oxygen reactions, and as a result, they are not impacted by light-induced degradation. This makes N-type solar cells a premium option as solar panels built with these degrade slower during their lifetime.

Which Ones To Get?

Most of the panels available today use P-type cells which degrade a bit faster but still keep good performance after 30+ years.

If you take into account the lower cost of P-type modules, it usually makes sense to go for a cheaper panel that degrades a bit more. For now.

N-type panels are substantially more expensive and provide slightly less degradation in practical terms.

As the N-type cell technology advances, let’s hope that widespread use will make these high-performing cells more affordable for homeowners.

Monocrystalline Solar Panels Use Cases

Before we go over the use cases, let’s outline the quick pros and cons of monocrystalline solar panels:

- High efficiency

- Less space needed

- More aesthetically appealing

- Better tolerance to heat

- Expensive

- Wasteful production method

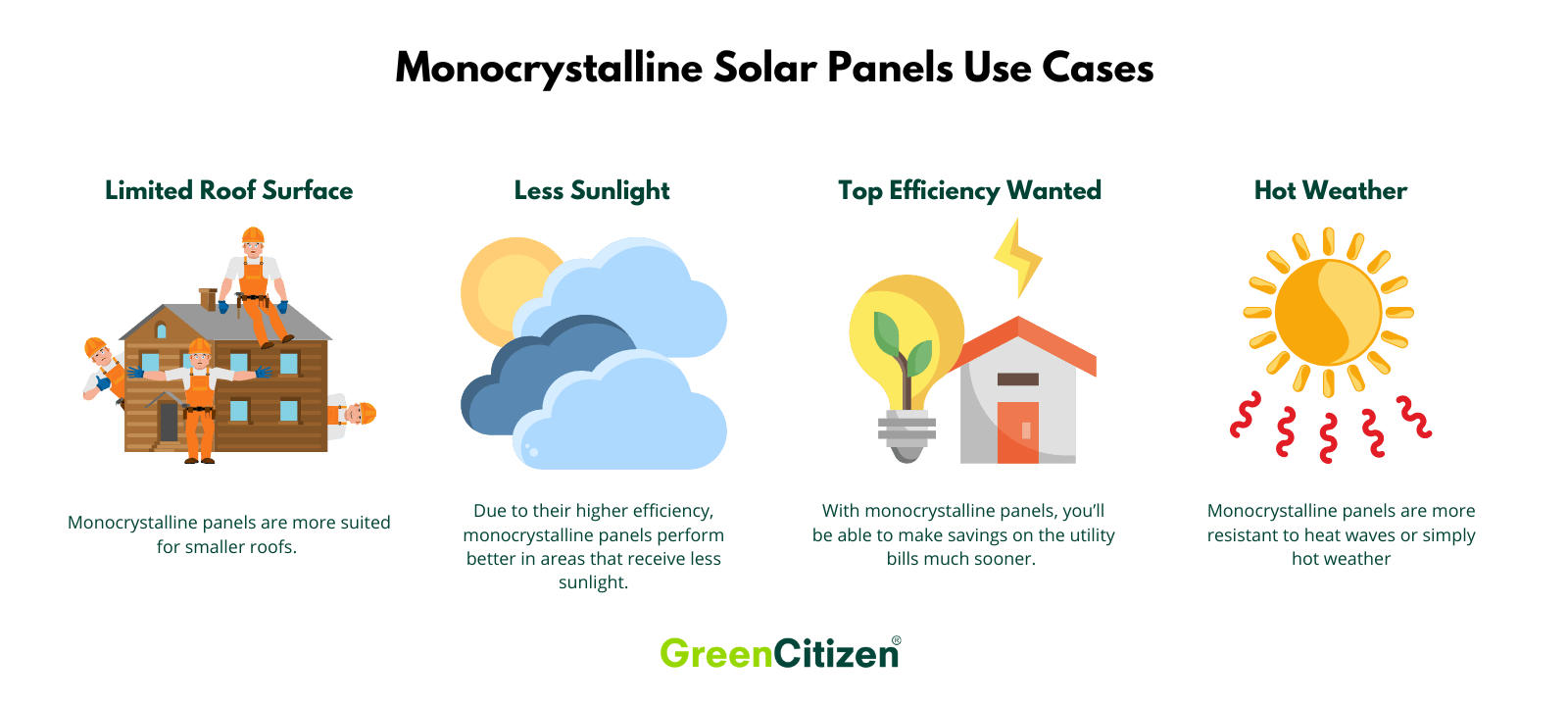

Limited Roof Surface

Monocrystalline panels are more suited for smaller roofs. They typically produce more power per surface of the panel, so you can achieve the desired wattage with fewer panels than if you went with polycrystalline panels.

The same applies to ground solar mounts.

If your roof is not suitable for solar panels for whatever reason — skylights, chimneys, gables, or different levels, you may have to use a ground mount.

In this case, it’s also much easier if you can get the job done with fewer panels.

Areas with Less Sunlight

Due to their higher efficiency, I can recommend monocrystalline panels for areas that receive less sunlight during the day. For example, your roof is in the shade of a large tree for a better part of the morning.

In another situation, your home might be situated near tall buildings that block the sun, making the solar panels operate with what reflected light they soak.

In both cases, monocrystalline panels provide a better ROI.

Top Efficiency Wanted

If the price is not that much of an issue, I say go for monocrystalline panels without thinking. If you’re leasing the panels, it’s normal that you want your investment to return as soon as possible.

With monocrystalline panels, you’ll be able to make savings on the utility bills much sooner.

If you can apply for a federal solar tax credit or one of your local renewable energy rebates, then the normally steep price of monocrystalline modules becomes more bearable.

Hot Weather

Monocrystalline panels are more resistant to heat waves or simply hot weather all year round. The single-crystal architecture of their cells has a high thermal coefficient, so the power output is not so affected by the outside temperature.

If you live in tropical or desert environments, or simply have a lot of hot days during the year, monocrystalline panels are a much better choice.

Polycrystalline Solar Panels Use Cases

We’ll be addressing the use cases in a minute, but first let's see the good and bad of polycrystalline solar panels:

- Much less expensive

- Easier production method

- Less wasteful manufacturing process

- More space needed

- Lower efficiency

- Bluish color more visible

- Less tolerance to heat

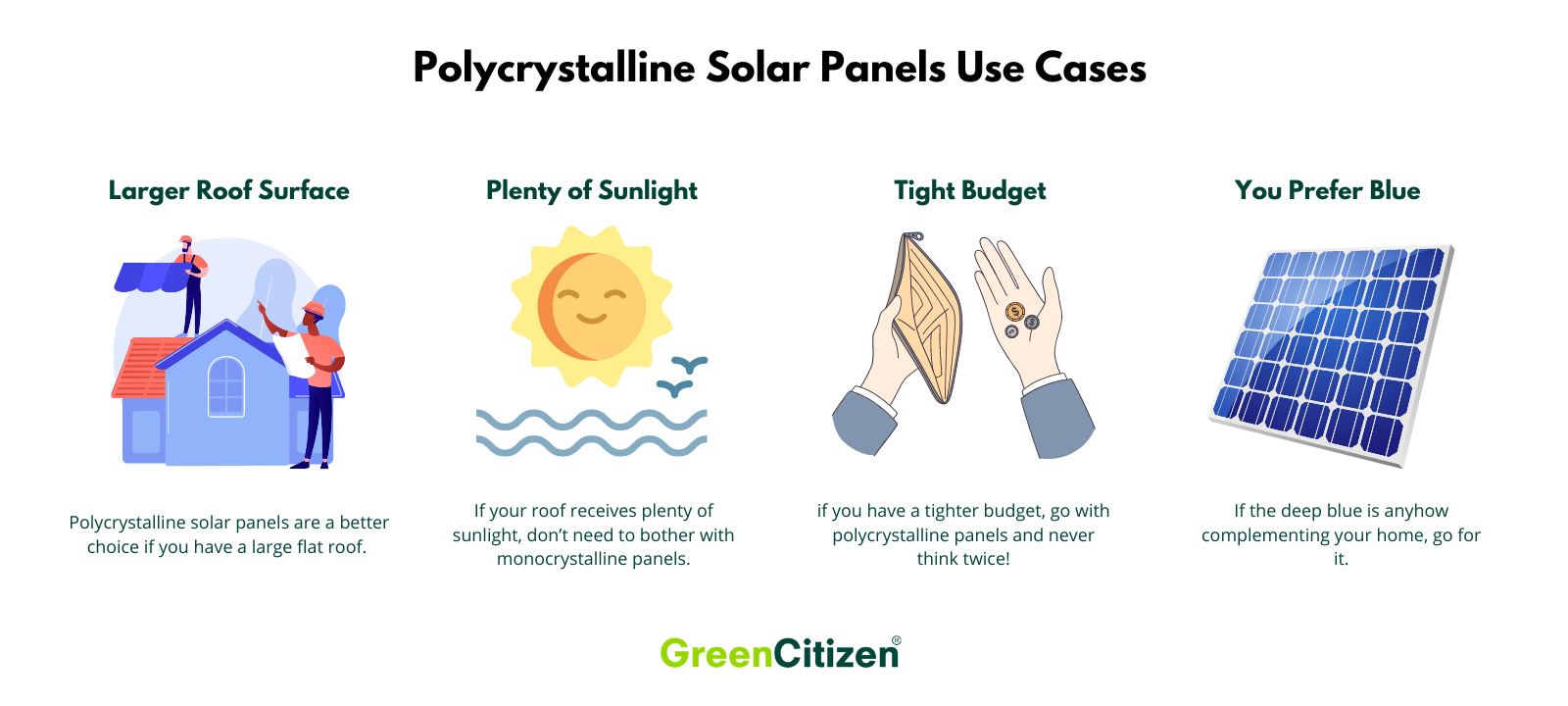

Plenty of Roof Surface

Polycrystalline solar panels are a better choice if you have a large flat roof with little or no architectural elements that could limit the number or position of panels.

If you’re going for ground mounts and have a huge backyard or a patch of farmland, there’s no need to break the bank with monocrystalline solar panels.

Just do your calculations and see how many polycrystalline panels you need, and you’re all set.

Plenty of Sunlight

If your roof receives plenty of sunlight, don’t need to bother with monocrystalline panels.

What difference do they make in efficiency, you’ll be able to match with long hours of sunlight. Also, if you live in areas that have a lot of sunny days, polycrystalline panels make much more sense.

Tight Budget

Let’s say you’re renovating your home and have already splurged a lot on structural repairs, new floors, and turning the basement into a habitable den.

And yet, you planned to cut some of the utility bills with a 5kW solar system.

I say you go with polycrystalline panels and never think twice. The technology behind photovoltaic modules is evolving and nowadays you can find poly solar panels with efficiencies that are close to those of mid-tier monocrystalline panels.

Aesthetics Not Important

People have been avoiding polycrystalline panels because of the speckled blue color that comes as a result of the silicon melting process.

In comparison with sleek dark monocrystalline modules, polycrystalline ones look a bit gadgety and out of place.

However, if the deep blue is anyhow complementing your home, go for it. Polycrystalline panels also make more sense for an off-grid cabin, where they’ll certainly be less visible than in suburban environments.

What Panel Type Is Best For Your Use Case?

The bottom line is that you should always consider your particular use case when choosing solar panels.

This is not a one-type-fits-all case!

First, let’s take the most common case — a family home.

If you own the home and don’t plan on selling it anytime soon, I’d invest in higher-end monocrystalline panels. They can work for over 30 years without losing much output thanks to the low degradation rate.

On the other hand, if you’re thinking of selling your home at one point, a cheaper polycrystalline system might add more value as a renewable energy feature. It definitely costs less up front and can help you cut the energy bills in the meantime.

Let’s now explore a scenario where you need solar panels for your animal farm or greenhouse.

Chances are that you'll have lots of flat roofs and won’t be too bothered by the aesthetics or limited by space. For these purposes, you should always consider polycrystalline solar panels first. They are less expensive and you can add as many as you need to cover your power usage.

Finally, let’s consider RVs and camping trailers.

Since the roof space on these vehicles is limited you need every inch you can get. This is why I usually recommend quality flexible monocrystalline panels which have higher output per surface ratio.

FAQ

Which solar panel is better: monocrystalline or polycrystalline?

Monocrystalline panels are generally more efficient and more resilient to weather extremes. This makes them a better choice for hot regions and locations which don’t receive direct sunlight the whole day. They also tend to degrade more slowly over time. However, they are the more expensive option.

Are Monocrystalline solar panels worth it?

Yes, monocrystalline solar panels are worth it if you need to meet your power needs with limited roof space. They are also a better choice if your roof doesn’t get enough sun.

What is the most effective solar panel?

Monocrystalline panels are the most effective solar panel type that is commercially available. The top-shelf products reach an efficiency of 23%, which is beyond any polycrystalline panel on the market.

What are the advantages of monocrystalline solar panels?

Monocrystalline solar panels have higher efficiency, work better at high temperatures, and degrade at a slower rate over the years. They also have a more visually-appealing look.

Which solar panel is best for high temperatures?

Monocrystalline solar panels are the best for high temperatures. They have a low heat coefficient which means that their efficiency doesn’t drop that much as the temperature rises.

How long do monocrystalline solar panels last?

Monocrystalline solar panels last more than 40 years. Manufacturers, however, usually provide warranties for 25 or 30 years.

How can you tell the difference between monocrystalline and polycrystalline?

You can tell the difference between monocrystalline and polycrystalline solar panels by the color and shape of their solar cells. Mono solar cells are dark or black and look like rounded squares of equal size. Poly solar cells are blue and appear like squares of different sizes.

Final Thoughts

In this monocrystalline vs. polycrystalline showdown I wanted to go through the advantages and disadvantages of the two most popular solar panel types.

The clear winner is hard to proclaim. I believe that most homeowners will be happier with monocrystalline solar panels, as the power output won’t be dropping on hot days.

Compared with less efficient polycrystalline panels, monocrystalline panels also allow you to meet the same energy needs with fewer panels on the roof.

This is a big thing if your roof space is limited.

On the other hand, if space is not an issue, if your roof gets plenty of sunlight, more affordable polycrystalline panels are a more reasonable option.

Renewable Energy

Monocrystalline vs. Polycrystalline Solar Panels: What Should You Get?

Written by : Nikola Gemeš | Last Updated: March 31, 2023

Contents

The monocrystalline vs. polycrystalline panel debate seems like an easy one. Yet poly cells are still alive and kicking. Find the answer!

If you considered buying solar panels for your home or off-grid cabin, you’ve probably come across terms such as monocrystalline and polycrystalline solar panels.

And these are no sales gimmicks like “surgical steel” or “non-slip handle”.

These two words refer to different technologies for manufacturing solar panel cells.

But why is that important?

Is there any significant difference?

As an electrical engineer, I’m well aware of both cell types and their industrial and commercial use.

But as home solar systems are becoming increasingly available, I have more and more people asking me, “What should I get? Monocrystalline vs. polycrystalline.”

I wrote this guide to help homeowners choose the best option for their solar system.

What are Monocrystalline Solar Panels?

Monocrystalline solar panels are solar panels made from monocrystalline solar cells or, as the industry calls them, wafers.

Monocrystalline solar panels consist of cells that are cut from a single silicon crystal. This feature gives them a uniform black look which users come to prefer. Since they are made from a single silicon crystal, these cells have fewer impurities. This allows them to perform better in high heat and lower-light environments.

These solar panels are generally considered a premium solar option due to their black color, higher efficiencies, and sleek aesthetics.

How It’s Made

In the lab, silicon crystal is grown into a cylindrical log shape called an ingot which is sliced into thin discs. Each disc is cut along the edges to form an octagon — a final shape of a solar cell.

This is important because when the solar cells are placed in the solar panel, the octagon shape helps fit a maximum number of solar cells for a given surface.

As a result, the manufacturing process for monocrystalline cells is more wasteful than the alternatives. Those corners that are cut from silicon wafers to make cell-shape discs have no further use.

This also makes these panels more expensive to produce and that price difference is passed on to a buyer.

What are Polycrystalline Solar Panels?

This manufacturing process gives polycrystalline panels a deep blue color.

If you look at them up close, you’ll see that the texture and color are uneven due to the way bits of silicon are blended together.

As there are more crystals in each cell, there’s less free space for electrons to move, which makes them less efficient than monocrystalline panels.

How It’s Made

To make polycrystalline solar panels, silicon crystal is left to cool down and fragment on its own. These fragments are melted at high temperatures and shaped into cubes that are cut into thin wafers.

So in this process, we don’t end up with a single silicon crystal but many different crystals molded, shaped, and cut into wafers.

You can compare it with baked potato chips: sliced from whole potatoes vs. made from potato mash pressed and molded into uniform chips.

The polycrystalline process allows for more cells to be produced from the same amount of raw materials.

This technology also produces less waste because there’s nothing to shave off or discard. All the raw materials are used in manufacturing.

As it is less demanding to produce polycrystalline than monocrystalline cells, the end product is also cheaper for the end-user.

Read More:

Buying vs. Leasing Solar Panels: Which Path Should You Take?

Monocrystalline vs. Polycrystalline Solar Panels?

Let’s now compare these two types of solar panels in categories that matter the most to end-users.

Cost

Monocrystalline solar panels use solar cells of high purity and require an altogether more complex manufacturing process. This makes them more expensive than polycrystalline panels.

However, homeowners often forget that a solar system includes other costs, as well, which are pretty much the same for both panel types. First of all, there's the solar inverter, electrical protections, wiring, rooftop mounts, labor, as well as permits and inspections.

Polycrystalline solar panels cost less but they are also less efficient. This means you can see a better return on investment with monocrystalline panels, especially if you’re limited by the number of panels.

Also, both types of panels are eligible for the federal solar tax credit.

Winner: Polycrystalline Solar Panels

Efficiency

Monocrystalline solar panels are generally more efficient than polycrystalline solar panels. This comes from the fact that their cells are cut from a single silicon crystal. To put it simply, the single crystal contains no impurities and the electrical current has less resistance to move through the cells.

But what is efficiency in solar panel terms?

Imagine you had 2 solar panels, one with an efficiency of 10% and the other with 20%.

If you expose both panels to the same amount of sunlight for the same duration, the second one will generate almost double the electricity.

The top-performing monocrystalline solar panels on the market reach efficiencies of 23%. The standard bestseller models typically have an efficiency of 15-20%.

In the same range, polycrystalline solar panels have efficiencies between 12% and 16%.

However, at the end of the day, the difference between these two solar panel types is not that big, especially if we’re talking about mid-range products.

Winner: Monocrystalline Solar Panels

Aesthetics

Monocrystalline solar panels consist of octagonal solar cells that look like rounded squares from a distance. Since they are made of pure silicon, they have a uniform dark look because of how lights interact with pure silicon.

This type of solar panel blends more naturally with dark shingles and foliage. It also makes your solar panels less of an eyesore. This is especially important if the local homeowner’s associations have strict rules on the homes’ curb appeal.

Polycrystalline solar panels, on the other hand, have a speckled blue look, as that's how sunlight interacts with melted silicon.

When it comes to aesthetics, it’s really up to personal preferences. Some users may prefer elegant and uniform black to keep up with the roof theme, others will discover that blue panels complement the swimming pool or the sky above.

Draw!

Lifespan

The lifespan of the solar panels is determined by the degradation rate or the yearly energy production loss.

Most solar panels on the market have degradation rates of 0.3% to 1%.

This means that every year, the power output of your solar system will drop by 0.3% to 1%.

Most commercially available solar panels have a yearly production loss of 0.3% to 0.8%.

Let’s say it is 0.5%.

After 10 years of use, your system will run at 95% efficiency. After 20 years, the system will still deliver 90% of its original output, and so on.

Unless there's physical damage, monocrystalline solar panels can keep running for more than 40 years, although with reduced efficiency. However, most manufacturers provide 25-30 year warranties.

In terms of lifespan, both monocrystalline and polycrystalline can well operate beyond their warrantied lifespans. That being said, polycrystalline panels have a slightly higher degradation rate.

Draw!

Temperature Coefficient

The temperature coefficient is a measure of how solar cells operate in hot weather. As you may remember from science classes, heat increases electric resistance and generates losses.

In this category, monocrystalline solar panels take an edge because their temperature coefficient is very low — between -0.3%/°C to -0.5%/°C.

This means when the temperature rises 1 degree Celsius or 32 degrees Fahrenheit, a monocrystalline solar cell efficiency drops by 0.3% to 0.5%.

Polycrystalline solar panels have a higher temperature coefficient than their monocrystalline counterparts, which means they’ll have weaker output when the temperature rises.

This is something to consider if you live in a hot region.

Winner: Monocrystalline Solar Panels

Read More:

Are Solar Panels Worth It? Opinions of An Electrical Engineer

Monocrystalline vs. Polycrystalline Solar Panels: Summary Table

Now to sum up the most important differences between monocrystalline vs. polycrystalline solar panels:

Nr.Crt

Solar Cell Technology

Monocrystalline

Polycrystalline

1

Cell Architecture

Single pure silicon crystal

Multiple silicon fragments molten together

2

Appearance

Uniform dark squares with rounded edges

Different blue squares with sharp edges

3

Conversion Efficiency

15% to 20%

13% to 16%

4

Temperature Coefficient (Losses)

Lower

Higher

5

Lifespan

25-40 years

20-35 years

6

Cost

Higher

Lower

Read More:

Cost Of Solar Panels In 2022: A Walkthrough Guide

N-Type and P-Type Solar Cells: What Should You Know?

In the previous sections, we covered the two most popular technologies to process raw material into silicon wafers — monocrystalline and polycrystalline.

Now we’ll explain how those wafers are further processed to turn them into functioning photovoltaic (PV) cells that can generate electrical current when exposed to light.

There are two types of solar cells that are created in these processes — N-type and P-type cells.

P-Type Solar Cells

P-type cells are typically built by adding a layer of boron on top of a silicon wafer. Since boron has one less electron than silicon, this combination produces a positively charged cell (P=positive).

P-type cells are prone to light-induced degradation (LID), which causes an initial drop in output as a result of light exposure. Over decades, this was the most common way to build solar cells. .

N-Type Solar Cells

N-type cells are doped with phosphorus, which has one extra electron than silicon, which creates negatively charged cells (N=negative).

N-type cells are immune to boron-oxygen reactions, and as a result, they are not impacted by light-induced degradation. This makes N-type solar cells a premium option as solar panels built with these degrade slower during their lifetime.

Which Ones To Get?

Most of the panels available today use P-type cells which degrade a bit faster but still keep good performance after 30+ years.

If you take into account the lower cost of P-type modules, it usually makes sense to go for a cheaper panel that degrades a bit more. For now.

N-type panels are substantially more expensive and provide slightly less degradation in practical terms.

As the N-type cell technology advances, let’s hope that widespread use will make these high-performing cells more affordable for homeowners.

Read More:

Best Flexible Solar Panels: Reviews & Buyer’s Guide

Monocrystalline Solar Panels Use Cases

Before we go over the use cases, let’s outline the quick pros and cons of monocrystalline solar panels:

Pros

Cons

Limited Roof Surface

Monocrystalline panels are more suited for smaller roofs. They typically produce more power per surface of the panel, so you can achieve the desired wattage with fewer panels than if you went with polycrystalline panels.

The same applies to ground solar mounts.

If your roof is not suitable for solar panels for whatever reason — skylights, chimneys, gables, or different levels, you may have to use a ground mount.

In this case, it’s also much easier if you can get the job done with fewer panels.

Areas with Less Sunlight

Due to their higher efficiency, I can recommend monocrystalline panels for areas that receive less sunlight during the day. For example, your roof is in the shade of a large tree for a better part of the morning.

In another situation, your home might be situated near tall buildings that block the sun, making the solar panels operate with what reflected light they soak.

In both cases, monocrystalline panels provide a better ROI.

Top Efficiency Wanted

If the price is not that much of an issue, I say go for monocrystalline panels without thinking. If you’re leasing the panels, it’s normal that you want your investment to return as soon as possible.

With monocrystalline panels, you’ll be able to make savings on the utility bills much sooner.

If you can apply for a federal solar tax credit or one of your local renewable energy rebates, then the normally steep price of monocrystalline modules becomes more bearable.

Hot Weather

Monocrystalline panels are more resistant to heat waves or simply hot weather all year round. The single-crystal architecture of their cells has a high thermal coefficient, so the power output is not so affected by the outside temperature.

If you live in tropical or desert environments, or simply have a lot of hot days during the year, monocrystalline panels are a much better choice.

Read More:

10 Best Portable Solar Panels (2022): Reviews & Buying Guide

Polycrystalline Solar Panels Use Cases

We’ll be addressing the use cases in a minute, but first let's see the good and bad of polycrystalline solar panels:

Pros

Cons

Plenty of Roof Surface

Polycrystalline solar panels are a better choice if you have a large flat roof with little or no architectural elements that could limit the number or position of panels.

If you’re going for ground mounts and have a huge backyard or a patch of farmland, there’s no need to break the bank with monocrystalline solar panels.

Just do your calculations and see how many polycrystalline panels you need, and you’re all set.

Plenty of Sunlight

If your roof receives plenty of sunlight, don’t need to bother with monocrystalline panels.

What difference do they make in efficiency, you’ll be able to match with long hours of sunlight. Also, if you live in areas that have a lot of sunny days, polycrystalline panels make much more sense.

Tight Budget

Let’s say you’re renovating your home and have already splurged a lot on structural repairs, new floors, and turning the basement into a habitable den.

And yet, you planned to cut some of the utility bills with a 5kW solar system.

I say you go with polycrystalline panels and never think twice. The technology behind photovoltaic modules is evolving and nowadays you can find poly solar panels with efficiencies that are close to those of mid-tier monocrystalline panels.

Aesthetics Not Important

People have been avoiding polycrystalline panels because of the speckled blue color that comes as a result of the silicon melting process.

In comparison with sleek dark monocrystalline modules, polycrystalline ones look a bit gadgety and out of place.

However, if the deep blue is anyhow complementing your home, go for it. Polycrystalline panels also make more sense for an off-grid cabin, where they’ll certainly be less visible than in suburban environments.

Read More:

Best Solar Panels For Home (2022): A Guide For Homeowners

What Panel Type Is Best For Your Use Case?

The bottom line is that you should always consider your particular use case when choosing solar panels.

This is not a one-type-fits-all case!

First, let’s take the most common case — a family home.

If you own the home and don’t plan on selling it anytime soon, I’d invest in higher-end monocrystalline panels. They can work for over 30 years without losing much output thanks to the low degradation rate.

On the other hand, if you’re thinking of selling your home at one point, a cheaper polycrystalline system might add more value as a renewable energy feature. It definitely costs less up front and can help you cut the energy bills in the meantime.

Let’s now explore a scenario where you need solar panels for your animal farm or greenhouse.

Chances are that you'll have lots of flat roofs and won’t be too bothered by the aesthetics or limited by space. For these purposes, you should always consider polycrystalline solar panels first. They are less expensive and you can add as many as you need to cover your power usage.

Finally, let’s consider RVs and camping trailers.

Since the roof space on these vehicles is limited you need every inch you can get. This is why I usually recommend quality flexible monocrystalline panels which have higher output per surface ratio.

Read More:

A Comprehensive Guide to Bifacial Solar Panels

FAQ

Which solar panel is better: monocrystalline or polycrystalline?

Monocrystalline panels are generally more efficient and more resilient to weather extremes. This makes them a better choice for hot regions and locations which don’t receive direct sunlight the whole day. They also tend to degrade more slowly over time. However, they are the more expensive option.

Are Monocrystalline solar panels worth it?

Yes, monocrystalline solar panels are worth it if you need to meet your power needs with limited roof space. They are also a better choice if your roof doesn’t get enough sun.

What is the most effective solar panel?

Monocrystalline panels are the most effective solar panel type that is commercially available. The top-shelf products reach an efficiency of 23%, which is beyond any polycrystalline panel on the market.

What are the advantages of monocrystalline solar panels?

Monocrystalline solar panels have higher efficiency, work better at high temperatures, and degrade at a slower rate over the years. They also have a more visually-appealing look.

Which solar panel is best for high temperatures?

Monocrystalline solar panels are the best for high temperatures. They have a low heat coefficient which means that their efficiency doesn’t drop that much as the temperature rises.

How long do monocrystalline solar panels last?

Monocrystalline solar panels last more than 40 years. Manufacturers, however, usually provide warranties for 25 or 30 years.

How can you tell the difference between monocrystalline and polycrystalline?

You can tell the difference between monocrystalline and polycrystalline solar panels by the color and shape of their solar cells. Mono solar cells are dark or black and look like rounded squares of equal size. Poly solar cells are blue and appear like squares of different sizes.

Final Thoughts

In this monocrystalline vs. polycrystalline showdown I wanted to go through the advantages and disadvantages of the two most popular solar panel types.

The clear winner is hard to proclaim. I believe that most homeowners will be happier with monocrystalline solar panels, as the power output won’t be dropping on hot days.

Compared with less efficient polycrystalline panels, monocrystalline panels also allow you to meet the same energy needs with fewer panels on the roof.

This is a big thing if your roof space is limited.

On the other hand, if space is not an issue, if your roof gets plenty of sunlight, more affordable polycrystalline panels are a more reasonable option.

Nikola Gemeš

Nikola, an electrical engineer, simplifies intricate sustainability subjects for his audience. A staunch environmental conservationist, he embodies his beliefs daily through recycling and cultivating his own food.

Quick Links

Green Living Guides

Green Jobs

Inspiring Green News

Green Directory

Green Store

Electronics Recycling

Category: Renewable Energy, Solar Power