At the end of their life, solar panels are a treasure trove of recyclable materials and rare elements. Done properly, recycling can save up to 96% of aluminum, glass, and semiconductor elements.

Solar power generation in people’s homes and through commercial solar farms has grown exponentially in the last 20 years. With the solar industry increasing power generation from 1.4 GW in 2000 to 760 GW in 2020, that also poses a significant impact on solar panel recycling.

But when you ensure that your old solar panels enter the cycle economy, you can ensure that up to 96% of the valuable materials contained in them end up in new solar panels and other electronic devices.

And to help you better understand the importance of proper solar panel disposal and how to do it, I’ve put together this complete guide.

Are Solar Panels Recyclable?

Yes, solar panels can be recycled. There are recycling technologies that achieve even 96% recycling efficiency, and the number is likely to grow even higher in the future.

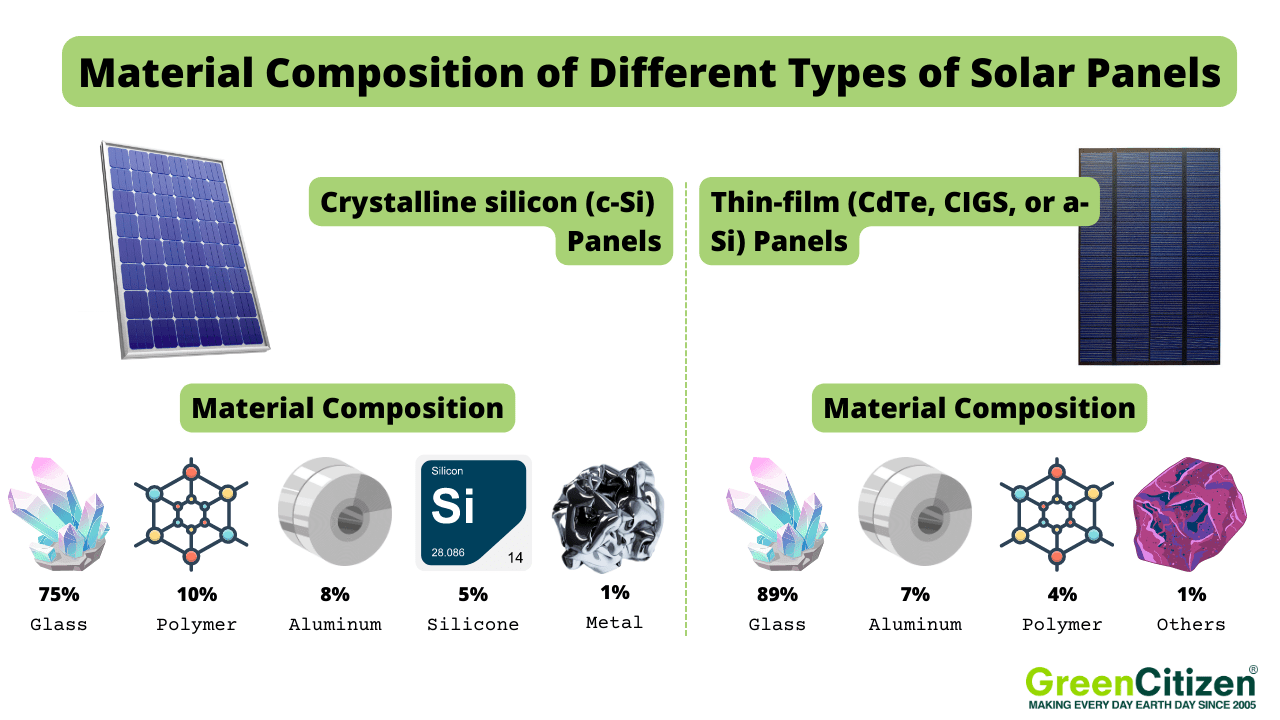

However, there are different recycling procedures for different types of solar panels.

These are the two main types in use today:

The common thing about both types of solar panels is that they are made of elements that can be recycled in mass quantities.

Metal, glass, and wiring can be recycled and reused completely.

Although you can’t simply break down solar-grade silicon wafers and recycle them like glass, some solar panels recycling companies melt them at high temperatures and reclaim silicon along with precious metals.

Why Should You Recycle Solar Panels?

We should recycle solar panels because although photovoltaic (PV) modules generate zero waste while operating, they will become e-waste at the end of their lifespan of about 25 to 40 years.

Here are the main reasons for properly recycling solar modules.

Environmental Importance Of Solar Panel Recycling

Whether you have a small and portable solar panel kit that no longer works or you have a damaged solar panel on your roof that needs replacing, there are important environmental factors to consider with all the materials they contain.

Many photovoltaic panels include heavy metals like cadmium and lead, which are toxic for humans and the environment when they leak out. That’s one of the primary reasons why end-of-life planning for solar panels is so important.

If solar panels are simply broken up and end up in a landfill, then those toxic materials will seep into the environment.

But there are other materials that have an indirect impact on the environment as they are heavily reliant on mined raw materials. From silicon to glass and copper, recycling and reusing these materials will reduce the need for destructive mining.

Extraction Of Valuable Materials

Solar panel recycling has also become an economically profitable process because of many valuable materials. Even just small amounts of gold and platinum add up, and the copper in the wiring has a lot of value too.

Where things get even more interesting and important is when it comes to rare earth metals. Not only are these very expensive to buy because of the huge demand for solar cells and other green technology, but the mining of these can also be very harmful.

That’s why end-of-life recycling has to focus on these metals to reduce the demand for mining operations and also significantly reduce the cost of these metals for the green energy sector.

Safe Removal Of Toxic Materials

I mentioned above that solar cells and panels often contain heavy metals that require recycling. In some cases, those can be safely extracted and then used again in the production of new solar panels or other electronics.

But sometimes, it’s difficult or unfeasible with current technology to extract all the toxic materials. And in those cases, you have to deal with a trusted solar panel recycling company to do the right thing and extract them before safely disposing of them.

The disposal of toxic materials is a highly regulated and very expensive process, which is why you should only deal with registered and certified recycling companies for all solar modules.

Economic Benefits Of Recycling

There are two ways to look at the economic impacts of solar panel recycling.

First of all, there are valuable materials like gold, platinum, and copper in pretty much any kind of electronic device. Those small amounts quickly add up to grams and ounces that can be worth a lot of money.

Secondly, there is also economic value in other materials like plastic or glass and even the aluminum frame of a solar panel.

It’s often much easier to collect such raw materials and reprocess them into a condition that allows them to be used in production again than it is to source the raw materials.

And with many raw materials having to go through costly mining operations and travel very long distances, it can quickly become cheaper to buy recycled materials.

What we will also probably see in the next few years is that solar panels will have a much longer life. This is something that the National Renewable Energy Laboratory has highlighted as a priority for the industry.

How To Recycle Solar Panels?

If you have an old or faulty solar panel, or part of your solar energy system is damaged due to a storm, then it’s important to take the right steps to properly deal with end-of-life processes.

It’s not just the ethically right thing to do, but there are legal reasons as well.

Let me explain.

Solar Panel Recycling Regulations

The Federal Government and EPA have taken steps in recent years to amend and introduce legislation around harmful and toxic materials. There have been regulations around electronic devices for many years, but solar panels somehow fell into a loophole.

Solar panels are now classified as solid waste and fall under existing regulations, according to information from the EPA. That means that hazardous waste and parts have to be dealt with by certified and registered companies.

In addition to federal regulations, individual states are also taking steps to ensure that end-of-life processing or solar panels reduce human and environmental impacts.

For example, California has taken things even further by adding solar panels to the Universal Waste Program.

And the Solar Energy Industries Association has been promoting industry-wide adoption of best practices in both production and recycling to make solar recycling easier and more efficient.

Simple Steps For Safe Solar Panel Disposal

If you have a relatively small solar panel system at home, then there are a few things you need to do to deal safely with the equipment.

First of all, unless you’re trained or experienced in installing solar panels, make sure that you have someone remove them from your roof safely. They are also quite heavy and awkward to handle, so you don’t want to be high off the ground on a ladder and try to handle it alone.

Once you have removed the solar panel from your roof, keep it somewhere dry and wrap it up to avoid damage. An old blanket is ideal for this.

Once you have made arrangements with a solar recycling company, carefully place the solar panel in your trunk and avoid any of the solar cells getting damaged during transport.

Silicon-based Module Recycling

Step 1: The solar panel recycling process for crystalline silicon products starts with taking apart the actual product to separate aluminum and glass. About 95% of glass can be reused. 100% of metal can also be reused for new frames.

Step 2: One way to loosen the binding between the cell elements is to heat them up to 500°C (932°F). During this process, the heat evaporates the encapsulating plastic, releasing the silicon cells. Other companies are researching much more energy-efficient technologies that achieve the same thing but also reduce the cost of recycling operations.

Step 3: Not even the encapsulating plastic goes to waste, as it becomes a heat source for the next stages of recycling.

Step 4: The remaining silicon wafers are etched away with acid or alkaline solution. Broken silicon particles are used again for making new silicon modules, with an 85% recovery rate.

Thin-Film-based Module Recycling

Step 1: The panels go into a shredder followed by a hammermill that produces particles 4-5mm particles. At this size, the lamination that keeps the inside layers sandwiched together breaks, so they can be separated. If the panel comes with the aluminum framing, the framing is removed before this step, allowing the aluminum to be reclaimed.

Step 2: Unlike with silicon-based PV panels, the remaining elements are in both solid and liquid form, so a rotating screw is used to move the solid parts to the next stage of recycling, while the liquid drips into a container below.

Step 3: The liquid component goes to metal processing that finally separates different semiconductor materials. About 95% of semiconductor components can be salvaged this way.

Step 4: The solid components are contaminated with interlayer elements that are lighter in mass, which are removed using a vibrating surface. What remains after the final rinsing is pure glass. About 90% of glass is saved in this recycling process.

Where To Recycle Solar Panels?

Now that you understand why it’s so important to extract recyclable materials in a safe way let’s take a look at how you can find a reliable company to deal with the mechanical recycling process.

Find Local Certified Recycling Companies

If your home solar panel has broken down and you’ve replaced it with a new one, then I suggest that you first find your closest solar panel recyclers. But you have to be careful not to end up with an uncertified company that might just be interested in extracting the valuable stuff.

The problem is that many companies look at recycling as a cash cow where they focus on the materials that they can sell at a profit, and they then ship the rest to developing countries.

In many cases, that leads to huge environmental damage and greenhouse gas emissions because they simply end up in landfills or are burned in the open air.

The right thing to do is to use the Green Directory and locate a registered and certified recycling company near you. You simply enter your zip code and name of the item you want to recycle (in this case solar panels).

GreenCitizen’s Solar Panel Recycling Services

If you live in the San Francisco Bay Area, then the best option you have is to drop off your faulty solar panels at the GreenCitizen recycling center. The process is very easy and efficient, with very convenient drop-off times.

First of all, simply use the contact form and provide details of the type of solar panel you have for recycling. You then need to weigh the panels in order to calculate the recycling fee.

At just $1.5 per pound, GreenCitizen offers one of the most competitive rates to properly recycle solar panels.

After that, you simply bring your panels to the Burlingame location drop-off point. You can pay the fee using contactless payment, and the whole process will take just a few minutes.

Challenges Of Solar Panel Recycling

There are a lot of challenges when it comes to recycling solar panels. And even though modern technology allows for a safe recycling process, it’s important to understand why you should only deal with certified recycling companies.

The International Renewable Energy Agency has reported that dealing with broken solar panels will continue to be a challenge. And it’s important to understand these challenges, especially if you’re planning a new installation.

See, if you ask the right questions before investing in the products of a solar panel maker, you can ensure that those panels will be easier to recycle in the future.

Let’s take a look at the challenges.

Mixed Materials

First of all, while there are countless different innovative designs for solar cells, they typically involve a mix of different metals like silver, copper, and aluminum held together with silicon.

Multiple cells are then bundled together using different types of plastic and poly in order to fully protect them from environmental damage, especially rain.

That design is extremely robust and, even in a very wet winter, won’t cause damage to the internal structure. But that robust design is also a drawback when it comes to recycling, as it’s not meant to be easy to dismantle.

The Breakdown Process

Removing the aluminum frame and external electronic components is the easy part. And these can almost immediately be set aside for reprocessing.

It gets a lot trickier when it comes to removing the glass front panel, as it’s tightly bonded to the underlying solar cells. And it’s important not to contaminate the glass with other materials like plastic and silicon.

It gets even more complicated to separate the metals from the poly and silicon that make up the core of a panel. The processes here are not high-tech, as you have to grind down the cells in order to free the metals.

Dealing with this in the right way to limit the impact on the environment takes certain skills and technologies, as well as a company dedicated to doing what is right at all times.

FAQ

Yes, even old solar panels are worth recycling. They contain rare metals like silver, indium, and tellurium that can be salvaged, as well as aluminum, copper, and glass that can be recycled and reused in new manufacturing.

You can get rid of old solar panels by selling them, giving them away, finding a scrap dealer who will take them, or paying for them to be recycled. After 30 years of service life, their power rating may not be enough for your home, but someone can still use them to charge an e-bike.

When solar panels end their service life, with a little luck, they become photovoltaic (PV) waste which can be recycled. Silicon-based modules consist of about 76% glass, 10% plastic, 8% aluminum, 5% silicon, and 1% rare metals. Current technologies reach 96% of recycling efficiency.

After 25 years, the efficiency of solar panels inevitably drops. If you maintain them properly, they may still work after 25 and even 30 years. However, if the output voltage drops way too low to power up the inverter, your panel has reached its end of life and needs to be recycled.

Conclusion

Taking your old solar panel to a landfill is a bad decision.

If toxic elements the solar panel contains are washed away, they can become both environmental and health hazards.

By dumping the panel, you are also dumping perfectly recyclable materials such as glass, aluminum, and copper, as well as rare elements like indium, silver, and tellurium, that can be salvaged and reused in new manufacture.

If it has reached its end of life, make the green choice, and drop off your intact solar panel at GreenCitizen's Burlingame Eco Center.

Do you guys have used panels for sale